ISO 9001 is a globally recognized standard for quality management systems. One of the key requirements of ISO 9001 is the implementation of a quality inspection checklist. This checklist serves as a tool to ensure that products or services meet the established quality criteria and comply with the organization's quality management system. It helps identify any non-conformities or areas for improvement, ultimately enhancing customer satisfaction and the overall effectiveness of the organization. In this blog post, we will explore the importance of a quality inspection checklist in ISO 9001 and provide practical tips for creating an effective checklist for your organization.

Quality inspection plays a vital role in ISO 9001 and is essential for upholding high standards and ensuring customer satisfaction. Organizations can identify and resolve any non-conformities or deficiencies in their products or services by conducting thorough inspections. This helps avoid costly rework or customer complaints and strengthens the organization's reputation and market competitiveness.

A well-designed quality inspection checklist is a crucial tool in this process. It enables organizations to systematically assess different aspects of their products or services, ensuring compliance with the established quality management system. By following a checklist, organizations can ensure consistency and standardization in their inspection processes and reduce the risk of overlooking any critical quality requirements.

Moreover, a quality inspection checklist helps organizations identify areas for improvement. By monitoring trends in non-conformities or recurring issues, organizations can implement corrective and preventive actions, further enhancing the effectiveness of their quality management systems.

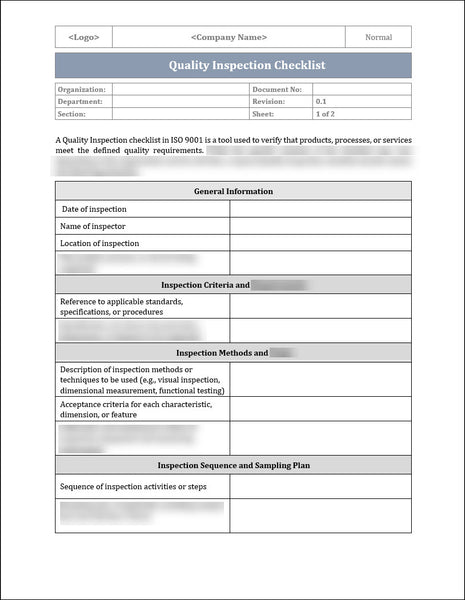

The International Organization for Standardization (ISO) 9001 is a globally recognized standard for quality management systems. One key aspect of ISO 9001 is conducting quality inspections to ensure that products and services meet the required quality standards. To facilitate this process, organizations often follow a quality inspection checklist. This blog will discuss the key components of a quality inspection checklist in ISO 9001.

1. Inspection Criteria and Requirements:

A quality inspection checklist's first component is defining the inspection criteria and requirements. This involves identifying the specific quality standards that need to be met, such as dimensions, performance specifications, or other relevant parameters. It is essential to clearly outline the acceptance criteria to determine whether the product or service meets the required quality standard.

2. Inspection Methods and Tools:

Once the inspection criteria and requirements are established, the next step is determining the inspection methods and tools. These methods can include visual inspections, measurements, tests, or other appropriate techniques for evaluating product or service quality. The checklist should specify the required tools, equipment, or instruments to perform the inspections accurately.

3. Inspection Sequence and Sampling Plan:

The inspection checklist should include the sequence in which inspections are performed. This ensures that all relevant aspects of the product or service are inspected systematically and organized. Additionally, the checklist should outline the sampling plan, which indicates the number of units that need to be inspected, as well as the selection criteria for the sample.

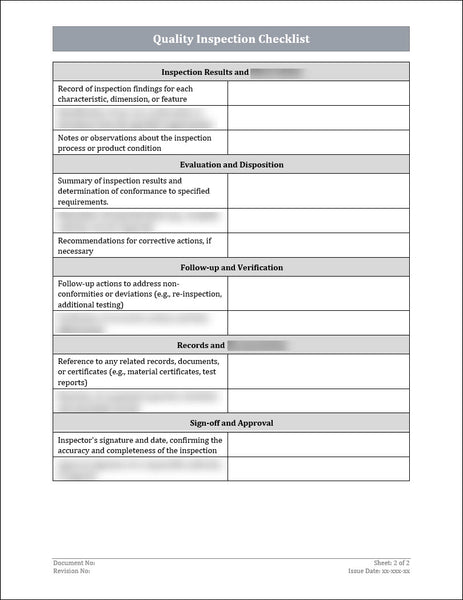

4. Inspection Results and Observations:

During the inspection process, recording and documenting the inspection results and any observations made is crucial. This allows for objective product or service quality information, which can be used for further analysis or improvement. The checklist should include fields or sections to accurately capture these results and observations.

5. Evaluation and Disposition:

Once the inspection is complete, the checklist should specify how the inspection results will be evaluated. This involves comparing the inspection findings against the defined acceptance criteria. Based on this evaluation, a decision must be made regarding the disposition of the inspected units, such as acceptance, rejection, rework, or further analysis.

6. Follow-up and Verification:

A quality inspection is not the end of the process. The checklist should include provisions for follow-up actions to ensure that any identified issues are appropriately resolved. This may involve tracking the corrective actions taken, verifying their effectiveness, or conducting subsequent inspections to ensure the identified issues have been resolved.

7. Record and Documentation:

Accurate and complete documentation is vital for maintaining quality records. The checklist should include fields to record essential information, such as inspection date, inspector's name, inspection results, and other relevant details. Having proper documentation to demonstrate compliance with ISO 9001 requirements is crucial.

8. Sign-off and Approval:

Finally, the quality inspection checklist must include provisions for sign-off and approval. This ensures that the inspection process has been completed per the defined requirements and that the inspected units meet the specified quality standards. Sign-off and approval formally acknowledge that the inspections have been carried out and the results have been reviewed.

In conclusion, a quality inspection checklist in ISO 9001 ensures that products and services meet specified quality standards. Organizations can maintain consistency and reliability in their quality inspections by including key components such as inspection criteria, methods, sampling plans, evaluation procedures, record-keeping, and sign-off. Implementing a comprehensive checklist can help organizations comply with ISO 9001 requirements and improve overall product and service quality.

A well-designed quality inspection checklist brings numerous benefits to organizations implementing ISO 9001 standards. Organizations can streamline their inspection processes using a checklist, enhance consistency, and improve overall efficiency.

One of the key benefits is the ability to promptly identify and address non-conformities or deficiencies in products or services. By systematically assessing different quality aspects, organizations can ensure that their deliverables meet customer requirements and adhere to the established quality management system.

Moreover, a quality inspection checklist provides a standardized inspection approach, reducing the risk of overlooking critical quality requirements. This standardization helps organizations consistently maintain high standards, improving product or service quality and customer satisfaction.

Another advantage of using a checklist is the ability to monitor trends in non-conformities. Organizations can identify recurring issues and proactively address them by recording and analyzing inspection data. This continuous improvement approach enables organizations to strengthen their quality management systems over time, enhancing operational efficiency and reducing costs.

In conclusion, implementing a quality inspection checklist is a powerful tool for organizations seeking to adhere to ISO 9001 standards. The benefits of using a checklist are multifaceted and can significantly impact an organization's overall efficiency, consistency, and customer satisfaction.

By promptly identifying non-conformities and deficiencies, organizations can ensure that their products or services meet customer requirements and adhere to the established quality management system. The standardized approach provided by a checklist helps maintain high standards consistently, leading to improved product or service quality.

Additionally, monitoring non-conformity trends allows organizations to take proactive measures for continuous improvement. Organizations can identify recurring issues by analyzing inspection data and strengthen their quality management systems over time.